IMOLD EDM is an automated module for designing and managing electrodes and their holders to assist the manufacturing of detailed and hard to machine features on mold nad press tools.

Electrode design can be one of the most complex and time consuming task for any mold or die maker. IMOLD EDM offers a solution to reduce design time. Even the most experience electrode designer will benefit from the knowledge-driven automation provided by IMOLD EDM.

IMOLD EDM makes it easy to design 3D solid electrodes from flexible surface extensions. The software offers an easy to follow, step-by-step process and addresses all of the common types of electrodes to the most complex ones.

fEATURES/ Function Includes:

- Electrode stock/blank sizing + positioning

- Solid + surface approach to designing electrodes

- Dynamic burn profile extraction

- Tangential, linear + angular surface extensions

- Vertical, side + inclined electrode simulation

- Rapidly perform design changes

Burn area extraction. After identifying the areas which need to be manufactured with an electrode, enclosing the area with a 2D or 3D boundary provides a quick and simple way to arrive at the required electrode geometry. Graphical face selection is also available to permit easy extraction of the more complex areas. Understanding that IMOLD EDM is a tool to compliment the experience of electrode designers, EDM combines automation with the ability to manually construct geometry and apply it to the electrode. This technology combination provides the user with the freedom to edit the design and ensures that it will always be possible to complete the electrode design.

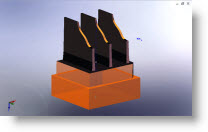

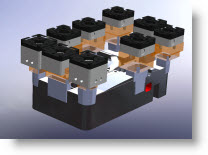

Blank, base and stock creation. The electrode base and stock are interactively added to the electrode or from a standard customizable library. Electrode name, material, burning operation type, identification marks, edge chamfers, position and rotation can all be applied. Any information added is automatically carried through the electrode project to the final report which, can be exported to PDF.

Holder creation. Holders can be constructed manually by applying width, depth or height, or simply selected from an extensive library. Where access for the electrode is limited by neighboring surfaces, the holder can be offset from the centre of the electrode to provide enough clearance for the EDM machine to

operate. Dynamic animation and collision checking ensure that the complete electrode does not violate the part geometry.

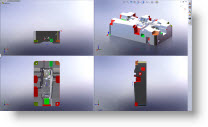

Documentation. Create and manage the electrodes, specify and control column content including stock size and export to PDF and txt. Shop floor documentation reports on all electrodes created with images and information relevant to burn location and electrode dimensions.

Electrode design. An intuitive Property Manager guides the user through the electrode design process. Options are available for adding extension distance with multiple vertical, angular or tangential extensions. Streamlining electrode designs with solid and surface approach. At any point within the electrode design process, dynamic preview of surface extensions assists the design.

Electrode management. The EDM manager provides the tools to effortlessly manage and toggle between the work piece, electrodes, multiple electrode positions, vertical, horizontal and angled simulation, choose documentation options.

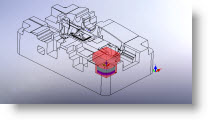

Datum and manufacturing. Specify datum on work piece and reference points on electrode blanks, lowest burn profile or reference options for easy referencing of burn location, travel distance and machine settings. Move along X, Y and Z coordinates, rotate blanks to optimize material.

Simulation and collision checking. To ensure that the electrode and holder are correct, the electrode can be graphically simulated along its axis of operation. Visual checking will test for interference between the electrode and work piece.